Product Assembler

Kaiwaihanga Taputapu

Alternative titles for this job

Product assemblers put together parts of metal products, machinery, electrical and electronic equipment, telecommunications equipment, joinery products and other goods.

Pay

Product assemblers usually earn

$48K-$50K per year

Source: Kelly Services, 2018.

Job opportunities

Pay

Pay for product assemblers varies depending on skills and experience.

- New product assemblers usually start on the minimum wage or a little more.

- Product assemblers with more than three years' experience can earn up to $50,000.

Source: Kelly Services, 'Salary Guide 2018', 2018.

- PAYE.net.nz website - use this calculator to convert pay and salary information

- Employment New Zealand website - information about minimum wage rates

(This information is a guide only. Find out more about the sources of our pay information)

What you will do

Product assemblers may do some or all of the following:

- follow assembly instructions

- place parts into position and check they're in the correct place

- punch or drill holes in the parts to be assembled

- bolt, screw, clip or weld parts together

- check the product for faults and modify if necessary

- pack the finished product

- service and operate computer-controlled systems that perform assembly tasks

- order materials.

Skills and knowledge

Product assemblers need to have:

- practical skills for working with machines, tools and materials such as aluminium or wood

- the ability to interpret technical drawings

- knowledge of safety rules and procedures.

Working conditions

Product assemblers:

- often do shift work, which may include nights and weekends

- work in workshops and factories, where conditions may be noisy and dirty

- may spend long periods sitting or standing.

What's the job really like?

Product assembler video

Find out about careers in production design and manufacturing – 3.11 mins. (Video courtesy of Competenz)

A career in product design and manufacturing has never been more exciting.

Let's take a look at Adept, New Zealand's leading product development and manufacturing company.

Adept makes a huge range of products from concept to design and final manufacturing. They make loads of stuff for other New Zealand manufacturers like Fisher & Paykel Healthcare – as well as their own products.

Over 95% of their products are exported to about 50 different countries overseas. So how does it start?

First up design engineers talk through the product requirements then they get to work designing a solution. They use specialist computer programmers to build, test and refine the design. When they're satisfied with a prototype it's ready for a team of tool designers to decide how to actually produce the item in a factory.

Tool designers work out the best way to manufacture the design. They look

at each component within the design which will be manufactured using a specialist process.

Every part of the design has to be detailed – it's like a giant jigsaw where CAD or CAM programmers create code to run CNC machines which then produce the individual components.

Each part has to fit together perfectly to work within the overall design. The verification process ensures that each part is perfect too micro accuracy.

It takes an army of skilled tradespeople to ensure all the elements in the design are manufactured to the highest standards. Everyone is a specialist in what they do.

Using highly technical equipment and specialist knowledge they can produce

the moulds that the factory will use.

There are so many job roles in the process – from production planning to material handlers, machine operators, die setters, composite fabricators, mechanical engineers, NC programmers and operators, along with the toolmakers, managers and designers. And everyone can take pride and get in each component exactly right.

With all component parts in place the factory comes alive.

You can see that there are still more roles on the factory floor in operating and maintaining the machiner. Assembly and cleanroom workers have a vital role to play in the manufacturing process, too.

And there is another specialist process fresh within the industry – composite fabrication. Carbon is the new business buzz, creating exciting new opportunities right now and with such fast-paced technology who knows what's just around the next corner.

So that's some insight into the world of design and manufacturing with huge thanks to Adept who are truly shaping tomorrow's world.

If you need help to shape your world for tomorrow why not talk to us about apprenticeship opportunities and on-the-job training.

Entry requirements

There are no specific entry requirements to become a product assembler as skills are gained on the job.

Product assemblers may complete the New Zealand Certificate in Manufacturing (Level 2 to Level 5) while working.

Secondary education

A minimum of three years of secondary education is recommended. Useful subjects include English, construction and mechanical technologies, digital technologies and maths.

For Year 11 to 13 learners, trades academies and the STAR and Gateway programmes are good ways to gain relevant experience and skills.

Personal requirements

Product assemblers need to be:

- safety-conscious

- efficient and practical

- accurate, with an eye for detail

- able to follow instructions

- good at problem solving

- skilled at communicating and listening

- good at basic maths.

Useful experience

Useful experience for product assemblers includes:

- electrical or electronics work

- mechanical engineering work

- work with hand tools such as soldering equipment

- work with metals, glass and machines

- welding.

Physical requirements

Product assemblers need to have normal colour vision and the ability to concentrate for long periods. They need to be reasonably strong as they might have to lift heavy loads.

Find out more about training

- Competenz

- 0800 526 1800 - www.competenz.org.nz

What are the chances of getting a job?

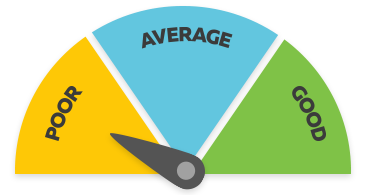

Poor opportunities for product assemblers

Chances of getting a job as a product assembler are poor because it's cheaper to make products overseas. Also, many products are now made by machines.

Many manufacturing companies have closed their factories or reduced their staff numbers due to a downturn in the industry.

According to the Ministry of Business, Innovation and Employment there are around 240,000 people working in the whole manufacturing sector.

According to the Census, 4,092 product assemblers worked in New Zealand in 2018.

Types of employers varied

Companies that employ product assemblers may create products that range from electronic radios to wooden furniture or windows.

Some small companies have fewer than five staff, while larger companies may employ 100 or more staff.

Sources

- Edmunds, S, 'Here's Where Manufacturing Jobs have been Lost', 16 February 2017, (www.stuff.co.nz).

- Competenz website, accessed September 2018, (www.competenz.org.nz).

- Infometrics, 'From Education to Employment: Megatrends Report', 26 June 2018,(www.infometrics.co.nz).

- Ministry of Business, Innovation and Employment, 'Beyond Commodities: Manufacturing in the Future' 2018, (www.mbie.govt.nz).

- Ministry of Primary Industries, 'Situation and Outlook for Primary Industries March 2017', March 2017, (www.mpi.govt.nz).

- New Zealand Herald, 'Steep Manufacturing Drop as Outages Hit Production', 10 September 2018, (www.nzherald.co.nz).

- Stats NZ, '2018 Census Data', 2019.

(This information is a guide only. Find out more about the sources of our job opportunities information)

Progression and specialisations

Product assemblers may move into management or supervisory roles.

Product assemblers may specialise in:

- aluminium and wood joinery

- carbon and plastics assembly

- electrical and electronics assembly

- machinery assembly

- metal or wooden goods.

Last updated 27 March 2024